The most advance technologies in the industry

CLEANING PROCESS

The cleaning process of rubber stoppers is the most delicate and technically demanding, For that reason our plant is equipped with the latest technology in cleaning and sterilisation. This efficient process removes pyrogens and ensures that our ULTRAPURE stoppers are flushed , cleaned and that the particles are removed.

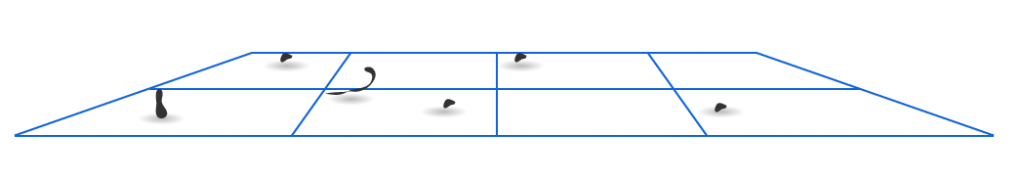

Contamination of stoppers before the process

Contamination of stoppers after the process

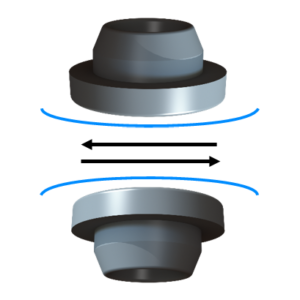

During the cleaning process, high pressure washes and rinses removing particles, manufacturing soils and any other chemical contamination. A treatment of pre-sterilization is applied to allow the extraction of water soluble components and mold release agents.

The air required for the drying step is pressed into the machine via a pre-filter, blower and .02 micron sterile filter. Drying is enhanced by centrifugation, which removes most of the water from the stoppers prior to the drying cycle.

The steam, at 121 degrees, continuously and uniformly is supplied via the nozzles which guarantees an optimum temperature distribution. During sterilization, the stoppers are smoothly shifted intermittently. Pressure and temperatures are permanently recorded according to FDA.

The most advance technologies in the industry

SURFACE COATING

In order to increase efficiency of moving rubber stoppers at high speed lines, various types and levels of surface coatings are applied during washing process.

This process creates slippery effect between rubber stoppers and the filling line facilitating trouble free functioning of stoppers filling operation on high speed lines.